Steel Deck Sheets vs Traditional Shuttering: Why Modern Construction Prefers Decking

Shuttering in Construction: Old vs New

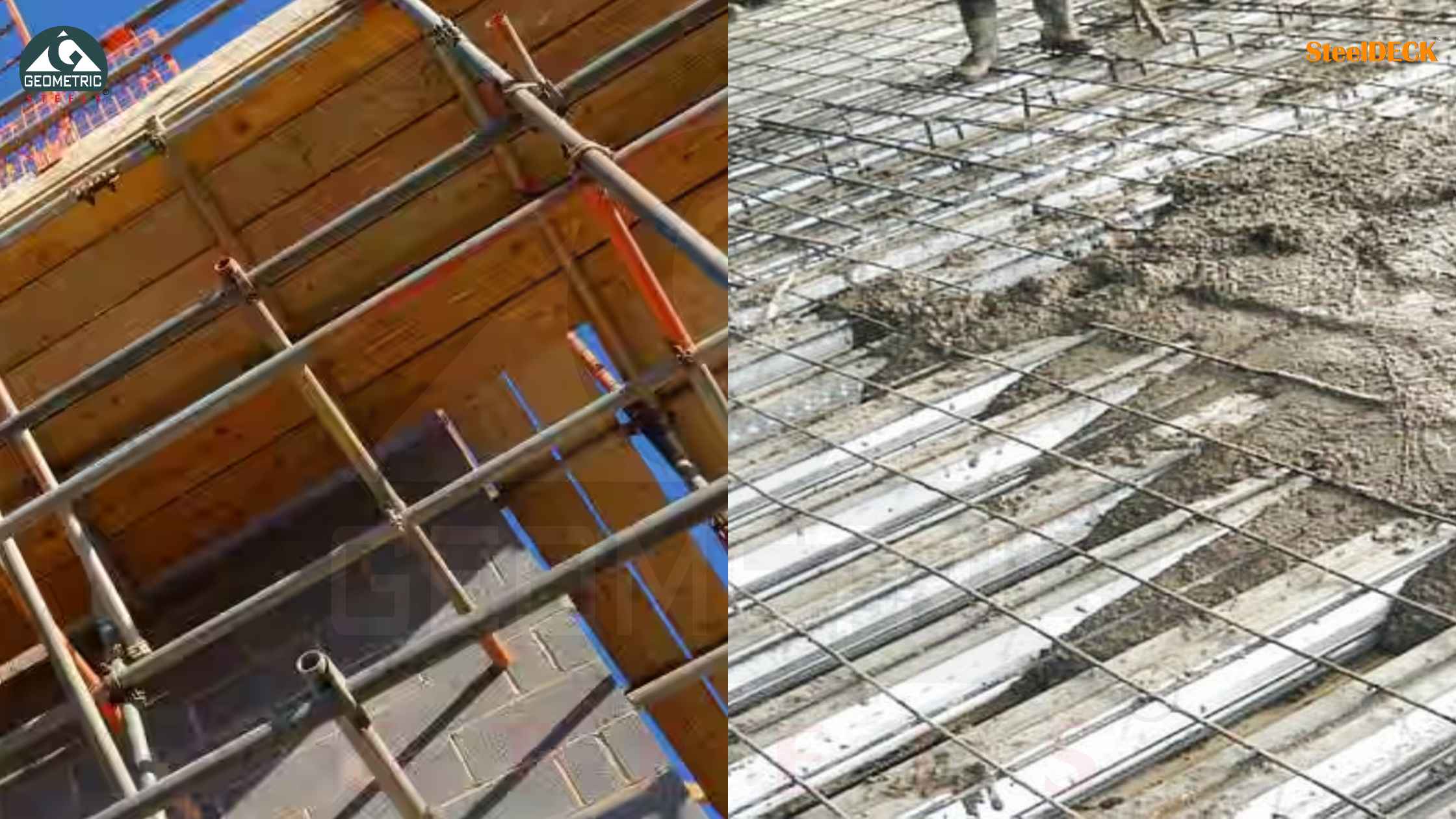

Every concrete structure needs shuttering (formwork) to hold wet concrete until it hardens. For decades, builders relied on traditional shuttering made from timber, plywood, or steel molds. While effective, this method is labor-intensive, time-consuming, and temporary, requiring removal after curing.

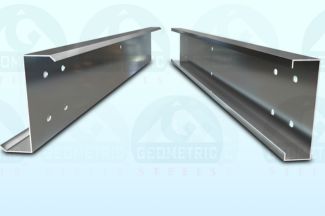

Modern projects, however, are turning to steel deck sheets—a system where precision-engineered metal decking sheets act as both formwork and a permanent structural component. Widely used in bridges, high-rise buildings, warehouses, and industrial flooring, decking eliminates many inefficiencies of conventional shuttering and provides long-term durability.

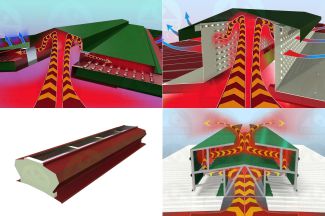

How Steel Deck Sheets Work

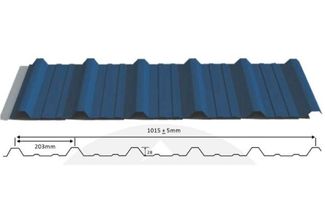

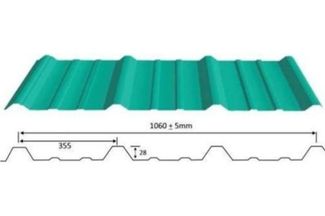

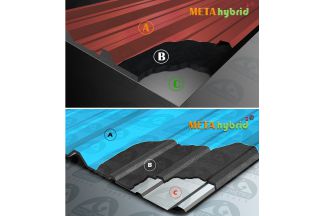

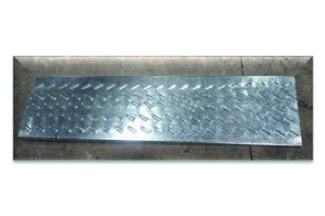

Steel deck sheets are profiled, embossed industrial decking sheets fixed to beams or joists. They provide a strong base for pouring wet concrete. Once the concrete cures, the sheets stay in place permanently, forming a composite slab decking system that is lightweight, durable, and high in load-bearing capacity.

Step-by-step process:

- Steel deck sheets are installed over the structural steel frame.

- Reinforcement bars are placed on top.

- Concrete is poured, filling the embossments for a strong mechanical bond.

- After curing, the slab acts as a unified composite structure.

This dual role—as steel deck formwork during construction and permanent reinforcement afterward—is what makes decking so efficient compared to traditional shuttering.

Advantages of Steel Deck Sheets

- Permanent Shuttering: The decking sheets remain part of the slab, saving removal costs.

- Composite Action: Concrete bonds with the steel decking, resulting in high-strength slabs.

- Speed & Efficiency: Construction can be 30–40% faster than with conventional shuttering.

- Lightweight Yet Strong: Lowers overall dead load, reducing foundation requirements.

- Reduced Material Waste: Cut-to-length supply minimizes on-site cutting and wastage.

- Improved Safety: The sheets provide a safe working platform for crews during construction.

- Cost-Effective for Large Projects: For industrial and commercial projects, faster timelines and reduced labor make steel deck sheets more economical.

- Easy Service Integration: Cable trays, ducts, and pipes can be fixed directly onto decking sheets.

Traditional Shuttering: Where It Still Works

Traditional shuttering still has its place in small or budget-sensitive projects. It is often made from:

- Timber/Wood: Versatile but prone to warping and water damage.

- Plywood: Creates smoother finishes, but has a limited lifespan.

- Steel Plates: Strong and reusable, but heavy and requires more labor.

Key limitations of traditional shuttering:

- High labor demand for setup and dismantling.

- Shorter lifespan for plywood or timber.

- More material waste.

- Slower project completion compared to steel deck sheets.

Steel Decking vs Traditional Shuttering: A Quick Comparison

| Feature | Steel Deck Sheets | Traditional Shuttering |

|---|---|---|

| Formwork Type | Permanent shuttering | Temporary shuttering |

| Speed of Construction | Fast (no removal needed) | Slow (requires setup & dismantling) |

| Strength | High – composite slab decking | Depends on timber/plywood/steel |

| Material Waste | Minimal (cut-to-size) | High (timber/plywood waste) |

| Labor Requirement | Low | High |

| Cost-Effectiveness | Best for industrial & large projects | Best for small projects |

| Safety | Provides safe work platform | Needs extra scaffolding & support |

Why Modern Construction Prefers Steel Deck Sheets

For today’s industrial and commercial projects, speed, safety, and efficiency are non-negotiable. Steel deck sheets deliver all three. They serve as construction formwork solutions that double as permanent reinforcement, reduce project timelines, and ensure stronger composite slabs.

While traditional shuttering may remain viable for small-scale construction, modern bridges, warehouses, factories, and high-rise buildings demand the strength and efficiency of industrial thermal insulated and decking sheets. This is why the industry is shifting towards steel decking vs plywood shuttering—a smarter choice for long-term durability and cost-effectiveness.

Contact Us

Looking for steel deck sheets that combine strength, speed, and cost-effectiveness?

Our expert team can help you choose the right decking profile for your project.

📧 Email: roof@geometricsteels.com

📞 Phone: +91 85509 95556

🌐 Website: www.steeldeckingsheets.com

Keywords: steel deck sheets, traditional shuttering, metal decking sheets, steel deck formwork, permanent shuttering, composite slab decking, industrial decking sheets, construction formwork solutions, steel decking vs plywood shuttering, decking sheets for concrete slabs